Isirinji elahlayo yokungunda/umngundo

Iimbumba zesirinji ezilahlayo zizixhobo ezibalulekileyo ezisetyenziselwa inkqubo yokuvelisa iisirinji ezilahlayo, ezisetyenziswa ngokubanzi kwi-injection kunye nokufakwa kwishishini lezonyango. Nantsi eminye imiba ephambili yokungunda kwesirinji okulahlwayo:

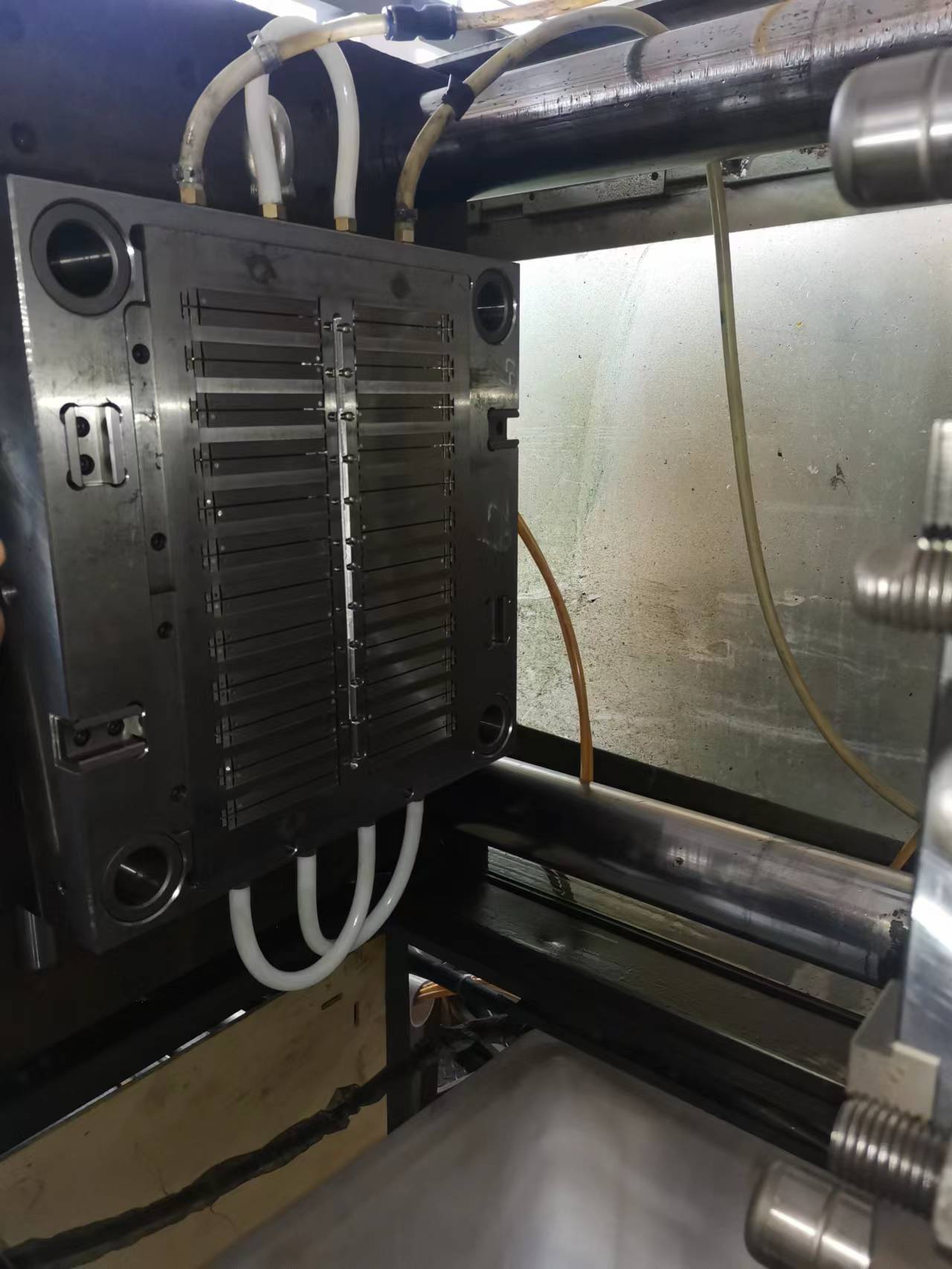

Uyilo lokungunda: Umngundo wesirinji elahlayo yenzelwe ngokukodwa ukwenza imilo kunye neempawu ezifunekayo kwindibano yesirinji. Ngokuqhelekileyo, iqulethwe ngamacandelo amabini, i-injection mold kunye ne-ejection mold, edibeneyo ukuze yenze i-cavity. Iimbumba zenziwa ngentsimbi ephezulu okanye i-aluminiyam ukumelana noxinzelelo oluphezulu kunye nobushushu obubandakanyekayo kwinkqubo yokubumba inaliti.

Isitofu seMaterial: I-mold ilungiswa kumatshini wokubumba ngokufudumeza i-raw material (ngokuqhelekileyo iplastiki yomgangatho wezonyango njenge-polypropylene) ide ifike kwindawo etyhidiweyo. Izinto ezityhidiweyo zifakwe kwi-mold cavity phantsi koxinzelelo oluphezulu. Ihamba ngeeshaneli kunye namasango ngaphakathi kwesikhunta, igcwalise i-cavity kunye nokwenza ubume bendibano yesirinji. Inkqubo yokutofa ilawulwa ngokungqongqo ukuqinisekisa ukuchaneka kunye nokuhambelana kwimveliso yesirinji.

Ukupholisa, ukuqinisa kunye nokukhupha: Emva kokuba i-material ifakwe, into etyhidiweyo iyaphola kwaye iqine ngaphakathi kwi-mold. Ukupholisa kunokufezekiswa ngeendlela zokupholisa ezidibeneyo kwi-mold okanye ngokuhambisa isikhunta kwigumbi lokupholisa. Emva kokuqina, i-mold ivuliwe kwaye i-syringe egqityiweyo ikhutshwe kusetyenziswa indlela efana nepini ye-ejector okanye uxinzelelo lomoya ukuqinisekisa ukukhutshwa okukhuselekileyo kunye nokusebenza kakuhle kwi-mold.

Amanyathelo okulawula umgangatho aphunyezwa kuyo yonke inkqubo yokuvelisa ukuqinisekisa ukuba iisirinji ziyahlangabezana neenkcukacha ezifunekayo kwaye zithobela imigangatho yezonyango. Oku kubandakanya ukujonga uyilo lokungunda, ukubeka iliso kwiiparamitha zenaliti kunye nokuhlolwa emva kokuveliswa kweesirinji ezigqityiweyo ukuqinisekisa umgangatho wazo, ukusebenza kunye nokhuseleko.

Lilonke, ukubumba kwesirinji esilahlwayo kuvumela ukuveliswa kobuninzi beesirinji ezilahlwayo, ezidlala indima ebalulekileyo kwindawo zokhathalelo lwempilo. I-mold iqinisekisa ukuba iisirinji zihlala ziveliswa kwiinkcukacha ezifunekayo, ukuhlangabezana nemigangatho yezonyango, kwaye zibonelela ngokusebenza okuthembekileyo xa zisetyenziselwa inaliti okanye ukuxutywa.

| 1.R&D | Sifumana umzobo we-3D yomthengi okanye isampuli kunye neemfuno zeenkcukacha |

| 2.Uthethathethwano | Qinisekisa kunye neenkcukacha zabathengi malunga: i-cavity, imbaleki, umgangatho, ixabiso, izinto eziphathekayo, ixesha lokuhambisa, into yokuhlawula, njl. |

| 3.Faka iodolo | Ngokoyilo lwabathengi bakho okanye ukhetha uyilo lwethu lwengcebiso. |

| 4. Ngundo | Okokuqala Sithumela uyilo lokungunda ekuvunyweni kwabathengi ngaphambi kokuba senze ukubumba kwaye emva koko siqalise imveliso. |

| 5. Isampuli | Ukuba isampulu yokuqala iphume ayonelisekanga umthengi, siguqula ukungunda kwaye side sidibane nabathengi ngokwanelisayo. |

| 6. Ixesha lokuhambisa | 35 ~ 45 iintsuku |

| Igama lomatshini | Ubuninzi ( iipcs ) | Ilizwe lokuqala |

| CNC | 5 | Japan/Taiwan |

| I-EDM | 6 | Japan/China |

| EDM ( Isipili) | 2 | Japhan |

| Ukusika ucingo ( ngokukhawuleza ) | 8 | eTshayina |

| Ukusika iiNcingo ( Phakathi ) | 1 | eTshayina |

| Ukusika ucingo (cotha) | 3 | Japhan |

| Ukusila | 5 | eTshayina |

| Ukugrumba | 10 | eTshayina |

| Lather | 3 | eTshayina |

| Ukugaya | 2 | eTshayina |